Choosing the right compressor?

What compressor do I need to paint a car. How to choose the correct air compressor for my spray gun (paint sprayer)?

Connect the compressor and wait for full working pressure. you can then adjust the pressure via a gun gauge which is connected to your spray gun.

Compressors are measured by their displacement in CFM (Cubic Feet per Minute). Spray guns are measured by the free air they use, the maths is for example a 12cfm displacement less a third equals the free air available.

The simple sum is (12cfm displacement minus 1/3 = 8cfm free air).

How to use a spray gun with an air compressor?

A spray gun that is driven by compressed air must be connected via an airline; it can be directly screwed to a threaded airline but is usually used with quick release connectors.

Low Noise / Screw Compressors >>

Portable Compressor Systems & Kits >>

What connectors do I need to connect my spray gun to air hose and compressor?

What airline and connectors do I need for my spray gun?

- Typically 3/8” (8mm) is the minimum airline internal diameter/bore. We recommend using pre-made airline that includes ¼” BSP female threaded nuts at either end.

- Quick release connectors screw in to the end of the airline primarily to pair/interconnect with a tail-piece. The spray gun tail-piece would have a female thread.

- View Airline & connectors >>

What are the different airline connectors?

- Male and Female thread (originates from the animal kingdom).

Example: ¼” BSP male thread screws into ¼” BSP female thread and forms a seal. Spray guns and fittings supplied by us in BSP >> with NPT >>

- Quick release coupling connectors tube type tails that push in to small barrel like receivers (sometimes confused or described as male and female BUT not in SprayGunsDirect language).

- Euro (HVLP) high flow connectors are best practice for use with a spray gun. Traditional / old-fashioned British connectors (often misleadingly referred to as PCL style) do not suit optimal air delivery for a spray gun.

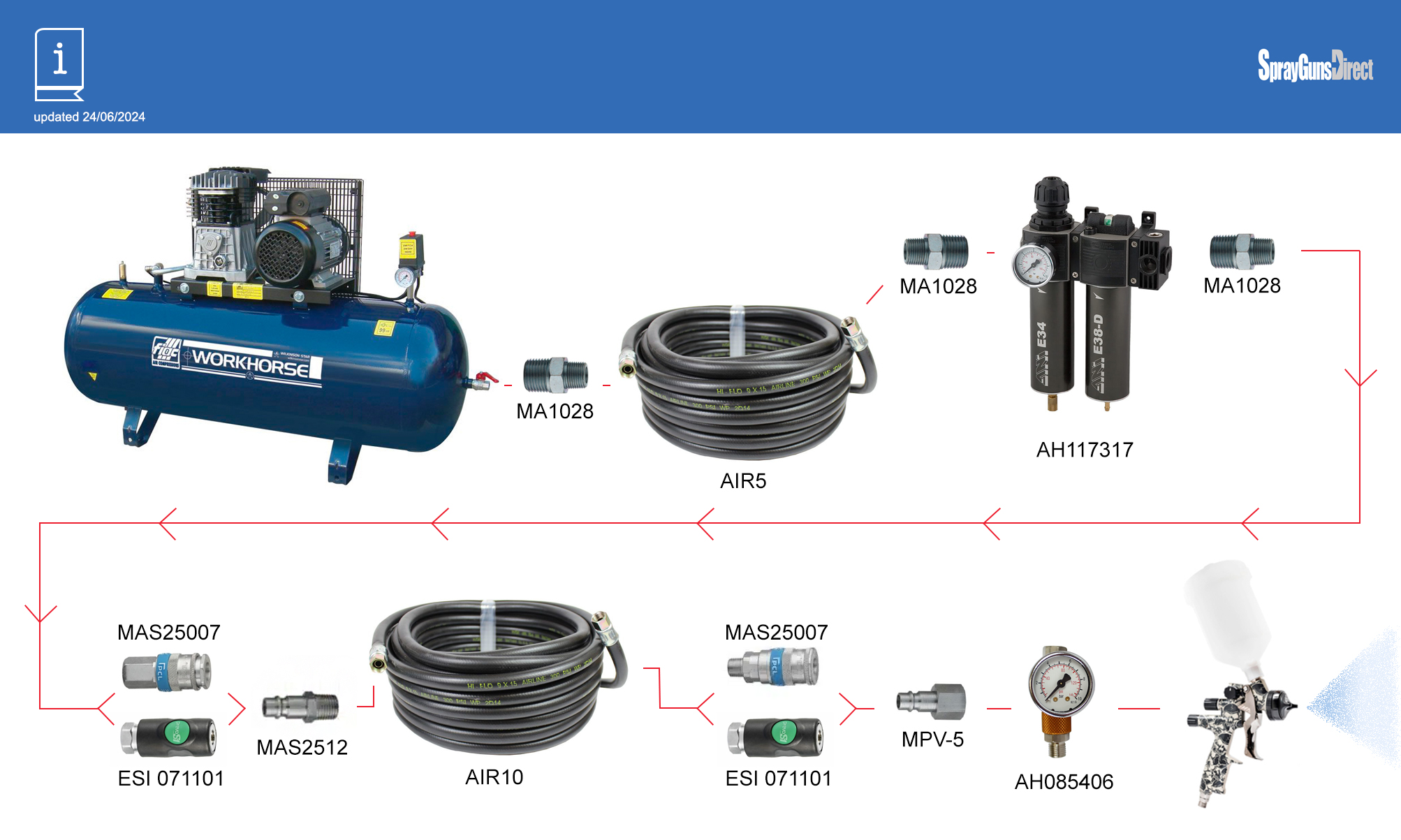

Below shows HVLP connectors used to connect the spray gun to air hose and then to the compressor. This method is quick release which is simple and very easy to use especially when changing devices using compressed air. For a full compressed air system a second air hose would be included along with a filter regulator. Air flow would typicaly follow this direction.

Compressor >> Air Hose >> Filter Regulator (1,2 or 3 stage) >> Air Hose >> Spray Gun Gauge (non-digital) >> Spray Gun

Next (quick guide) – Connecting your Spray Gun to your Compressed Air System Hose

Back to #welovesprayguns